E-mail address

-

-

Telephone number

(+39) 0721 - 624290

E-mail address

Telephone number

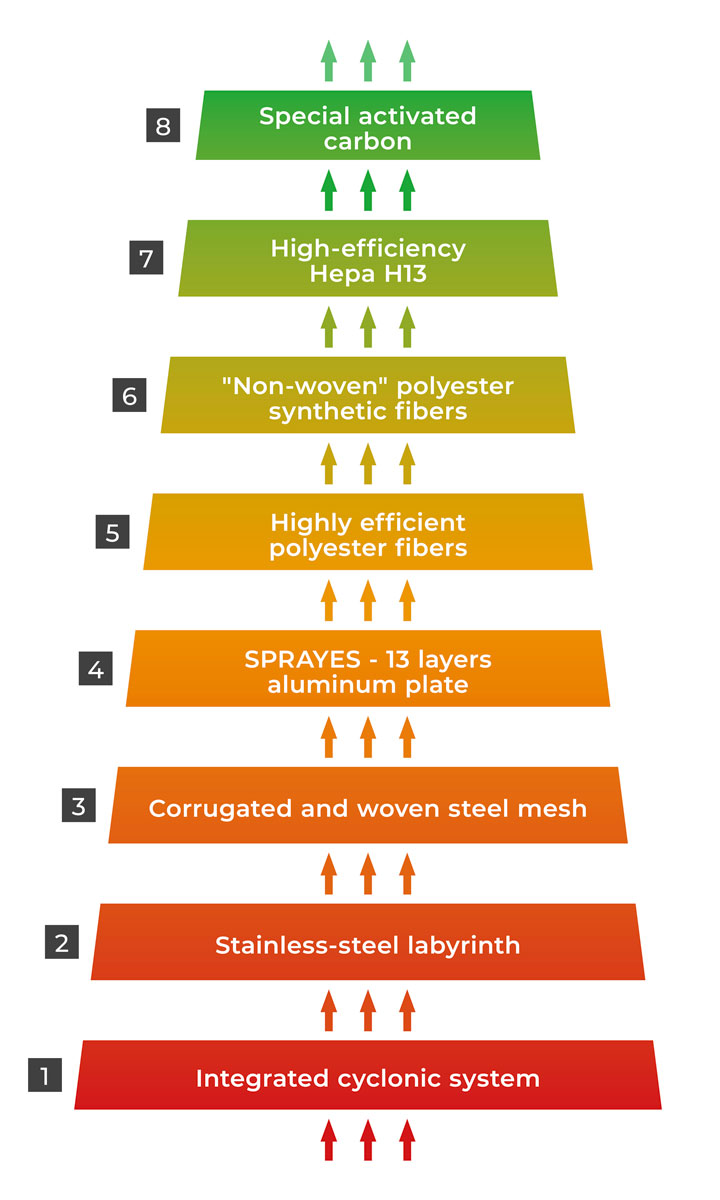

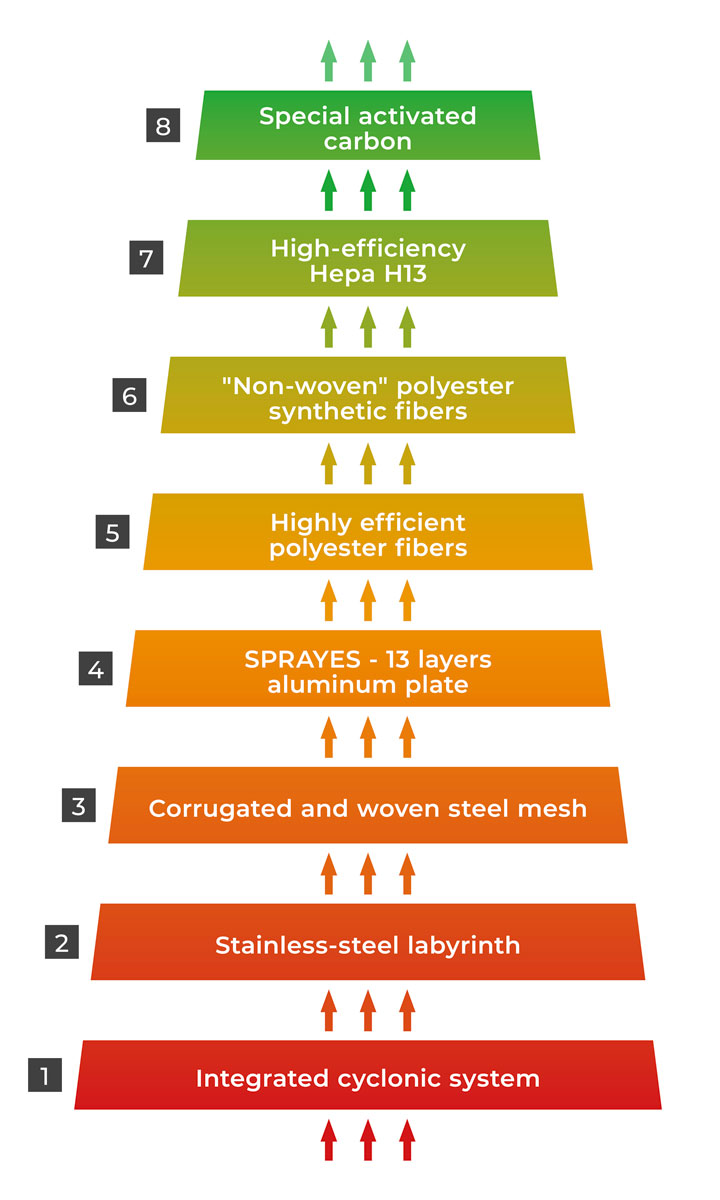

The only oil and mist collector that can include up to 8 filtering stages

The innovative Italyvacuum collectors and extractors dedicated to the oil and mist division arise from the need to eliminate oil mists, vapors, fumes that come from the most varied processes in order to make the work atmosphere as healthy as possible, contributing at the same time to safeguarding of the environment.

A careful market analysis by Italyvacuum technicians has led the company to develop this advanced line of products in the full awareness of being able to simplify and improve what has already been available on the market up to now by applying its own technology and making it more efficient and much less expensive all maintenance operations.

They are available in 4 different models and in all voltages and frequencies on the world market.

The entire range is also available in stainless steel for harmful vapours, corrosive mists or for hazardous environments (Atex).

GENERAL INFORMATION

Volume of treated air: from 500 m3 to 3300 m3 ( 300 cfm to 2000,cfm )

Air inlet diameter: 150mm ( 5.90” )

Power: 0,55 kW ( 0,75 hp ) – 1,1 kW ( 1.5 hp ) - 1,5 kw ( 2 hp ) – 2,2 Kw ( 3 hp )

Tecnomist can undoubtedly include an enviable and very efficient oil mist filtration system not only due to the numerous filtering stages present inside it but above all, due to the innovative technologies used by the company for the removal of oil particles Filter group.

Filtering stages:

1st stage ) First of all, the powerful integrated cyclone which alone manages to break down 95% of the contaminating particles so that only a small percentage of them is able to come into contact with the subsequent filters.

This level of filtration is due not only to the centrifugal force which makes it possible to make the most of the coalescence effect but Italyvacuum has added to these two effects an obligatory spiral path of the air flow so that even the lightest contaminant microparticles are automatically expelled from the first moment towards the collection and recycling channel

2nd stage ) Stainless steel labyrinth filters with parallel staves - boasting a very high level finish - operate according to the principle of inertial separation by trapping the bulk of the micro drops that are transported by the air flow, thus protecting the subsequent filters. This filter is washable.

3rd stage ) Filter in corrugated and woven steel mesh also capable of blocking any metal residues - 4 high-density superimposed layers. It is washable

4th stage ) Special filter called SPRAYES made up of 13 layers of expanded aluminum plate with a surface density of 2 Kg/m² ( 0,41 lb/ft² ) and a thickness of 1.5 cm (0.59” ) with a weight efficiency of 71% and an accumulation capacity of 1 Kg/m² ( 0,20 lb/ft² ), protects against flows of gaseous substances containing grease. Filter is washable.

5th stage ) Filter made of long-lasting, highly efficient polyester fibers - excellent drainage qualities of both oil and any other types of refrigerants. Filter is washable.

6th stage ) White polyester filter defined as a "non-woven" because it is made up of synthetic fibers of various densities, lengths and curls.

The fibers are bonded by fusion (thermo-bonded) and the resulting structure is a random arrangement of the fibers which, thanks to its particular progressive structure, allows lower pressure drop increases compared to filters with a homogeneous structure. This filter is also washable.

7th stage ) High efficiency Hepa H13 filter specially designed for the reduction of oil micro-particles and related bacteria with 99.95% efficiency

Among its particularities emerge the heat-sealed separators which, thanks to their conformation, increase the filtering surface and are able to maintain a uniform spacing between the pleats allowing an optimal air flow

They are made entirely of polystyrene, completely incinerable and halogen-free and can operate with maximum efficiency up to temperatures of 70 °C

Optional filter

8th stage ) Possibility of inserting an optional activated carbon filter to reduce odors.

Strada Della Fabbrina, 6/E

61122 Pesaro (PU)

Call us by phone

(+39) 0721 - 624290Write us an e-mail

infoitalyvacuum.com