E-mail address

-

-

Telephone number

(+39) 0721 - 624290

E-mail address

Telephone number

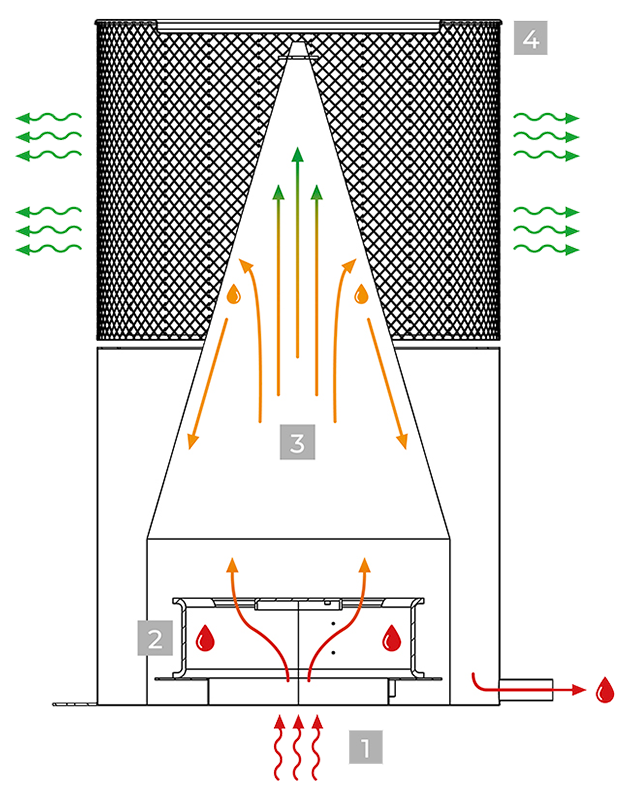

MASTER MIST – The innovative collectors by Italyvacuum dedicated to the oil mist division, arise from the need to eliminate oil mist, vapors, smoke, fumes that come from the most diverse processes, in order to make the work environment as healthy as possible, contributing at the same time to environmental protection.

A careful market analysis by Italyvacuum technicians has led the company to develop this advanced line of products in the full awareness of being able to simplify and improve what has been available on the market up to now, by applying its own technology and making it more efficient yet much less expensive for all maintenance operations.

This product enjoys a European patent thanks to the numerous innovations it contains.

It is available in 6 different models and in all voltages and frequencies on the world market.

The entire range is also available in stainless steel for harmful vapors, corrosive mists or for hazardous environments (Atex).

GENERAL INFORMATION

Volume of filtered air: maximum 1500 m3 / h ( 900 CFM )

Filtering group: 3 stages + Hepa

Air inlet [ Ø ]: 120mm ( 4.72" )

Strada Della Fabbrina, 6/E

61122 Pesaro (PU)

Call us by phone

(+39) 0721 - 624290Write us an e-mail

infoitalyvacuum.com